KREIDER offers coated (MK-60T, MK-90T) and uncoated (MK-60, MK-90) grades of fine GCC for the production of plasticized PVC (plastic) products such as cable, film, hoses, flooring materials, artificial leather and others. To plasticized PVC producers, naturally sourced calcium carbonate provides several advantages in extrusion and calendaring, improves physical and mechanical properties of the final product and reduces the cost of the finished product.

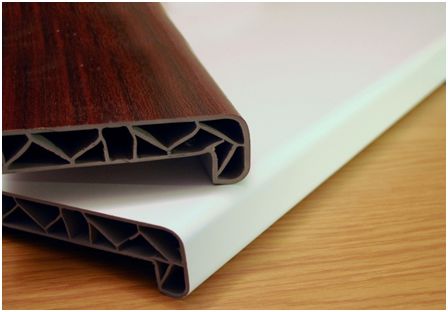

In the production of rigid PVC (siding, window stills, pipes, panels, colored windows, cable channels, etc.), KREIDER’s coated calcium carbonate MK-90T & MK-60T grades are used in order to obtain optimal physical and chemical parameters of the finished product.

High-quality stearic acid treatment of MK-90T and MK-60T makes our calcium carbonate fillers maximally compatible with polymer compositions and provides the following technical advantages:

- improved of mixture homogenization (no agglomerates in the mixture)

- reduced adsorption of other components

- lower lubricant & stabilizer content

- increased resistance to ageing

- improved rheological (flow) properties

- increased productivity

- more efficient use of raw materials

The selection of the right GCC grade is essential in order to obtain the maximum benefit from the use of KREIDER’s fine calcium carbonate for your production of PVC products. The final product’s properties are determined by a combination of factors such as the type of PVC, amount of plasticizer, formulation and filler particle sizes.